In my mums’ garage roof space there lurked an old separates tape deck. A venerable TEAC V-600 Last time it was used, many years ago, it chewed tapes badly. At the time I didn’t really need it, so into the loft it went… Turns out that was a bad move! Sorry little Teac… Maybe I can make amends and bring you back to life? I don’t have many music tapes anymore, but I DO have a ton of computer tapes and need to begin the process of archiving then in a digital form. If this works, stay tuned for this process in the future.

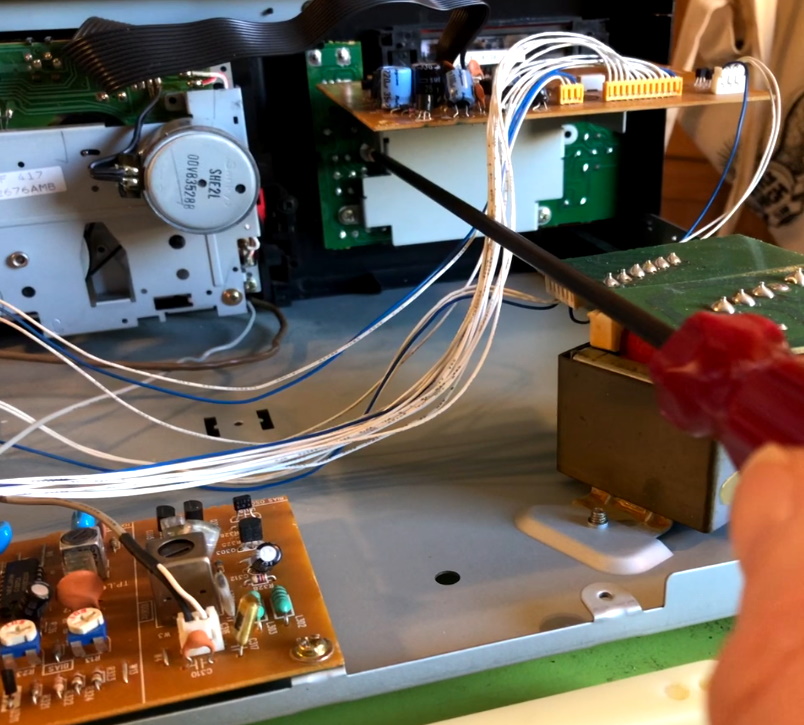

The Teac in question here is a non direct-drive units, meaning belts, meaning future problems. Upon inspection of the units, it was indeed belts that had perished. They had got stuck on the motor pulley in fact and looked terrible. Nothing was turning at all. Pulled them off and ordered a set of replacement belts.

There are still direct replacements for the TEAC V-600 available, from Germany, as far as I could tell. Great to see such stuff still being made/sourced. However, at £25 each plus £20 postage, that is far too steep. A quick search on eBay found a bundle of 20 belts of various sizes at £2.50! Result. Got them and they fit very nicely.

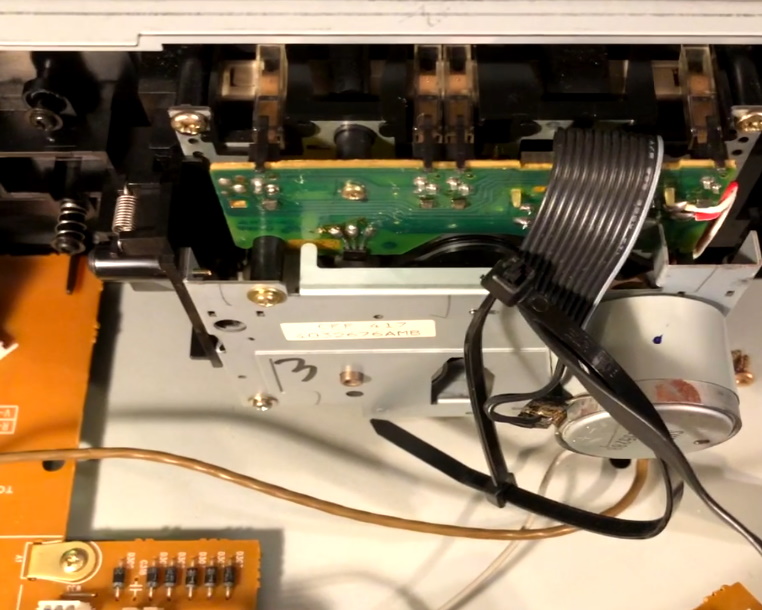

So that was the easy bit. In my efforts to remove the carriage, I tried to remove the connector to the display daughterboard. That did not go well:

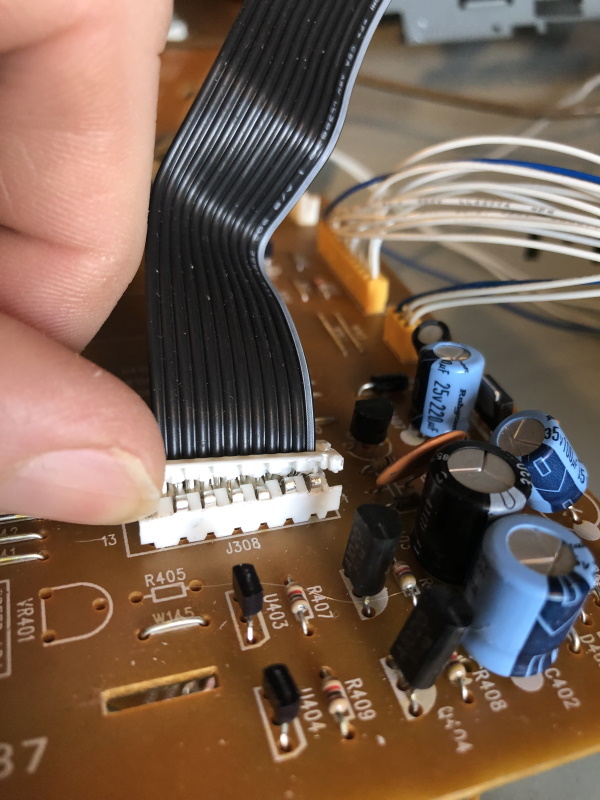

Bugger! Thats the result of reute force and ignorance! I thought it was an easy pop-off affair but turns out it wasnt and I broke the case, causing 3 of the cables from becoming intermitent. If you held the cable in a particular direction it works but it was far to dodgy. I have to face the fact I have broken this and need to repair. So next step is to remove this from the board and take a look:

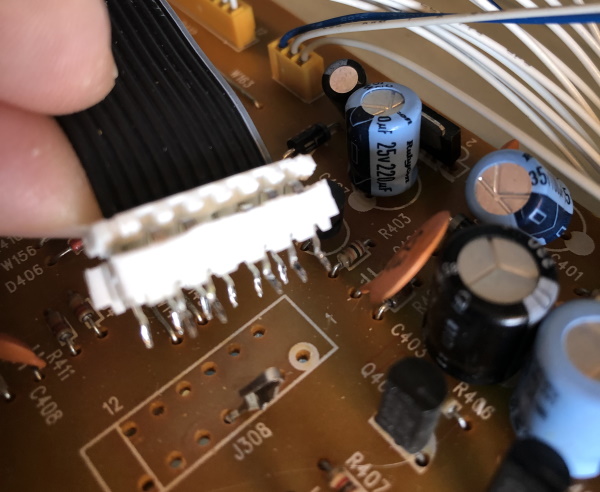

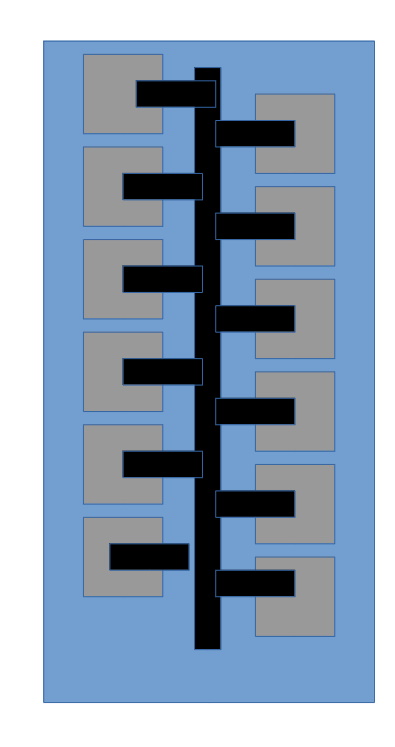

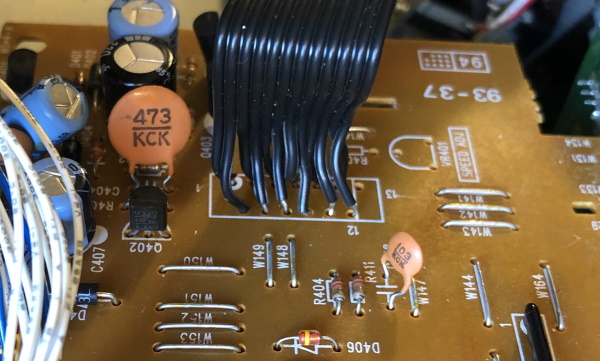

It was actually easy to resolder and the board remained intact. You can see one of the pins left in the board that came away when I pulled it off. The underside of the PCB cleaned up nicely. The wiring is staggered, with each next connection in the ribbon cable jumping left and then right:

The results worked, even if it looks a bit rubbish. It is one of the issues with thin ribbon cable in that the wire covering tends to melt easy when soldered and exposes more metal than wanted:

It works but need to add some hot glue to this so that it is kept in tact… but ran out of glue and want to test this first and see if everything is ok:

80’s tech and some 80’s music to go with it!

In fact the sound is quite good.

Tips

As a useful tip I would suggest getting yourself a VERY long screwdriver. I have had this long cross blade Stanley screwdriver for years. It is magnetic, strong and long. VERY useful: